The Future of Pharmaceutical Manufacturing: Automation, Continuous Production, and Smart Factories

Pharmaceutical manufacturing is undergoing a profound transformation, driven by automation, digitalization, and advanced quality control systems. These innovations not only improve production efficiency but also enhance drug safety, regulatory compliance, and overall patient outcomes. As the industry adapts to increasing global healthcare demands, modern manufacturing strategies are redefining the standards for speed, precision, and sustainability.

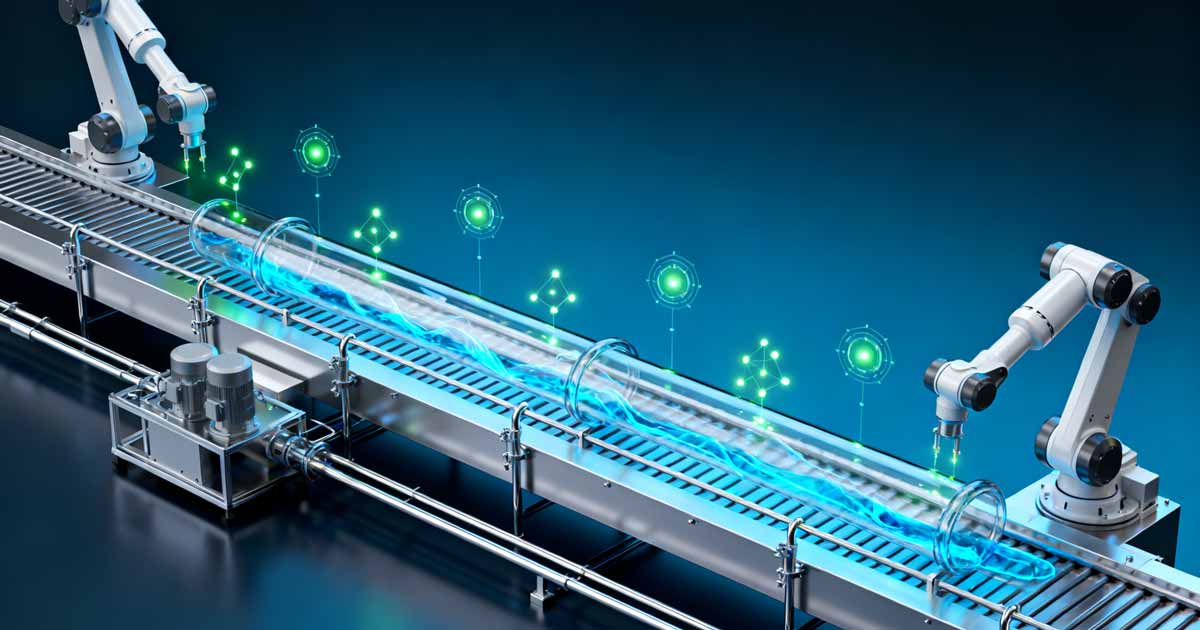

Automation and Robotics

Automated systems are revolutionizing pharmaceutical production by streamlining operations and minimizing human error. For instance, robotics handle repetitive tasks such as tablet filling, packaging, and inspection with unmatched accuracy. As a result, manufacturers achieve consistent product quality while reducing labor costs and the risk of contamination. Moreover, automation allows staff to focus on high-value tasks such as process optimization and innovation, enhancing overall operational efficiency.

Continuous Manufacturing

Unlike traditional batch processing, continuous manufacturing maintains a constant product flow, significantly improving efficiency. This approach reduces waste, lowers energy consumption, and shortens production timelines. By enabling real-time monitoring and control, continuous manufacturing ensures that any deviations are immediately detected and corrected, maintaining product quality and regulatory compliance. Consequently, pharmaceutical companies can respond faster to market demands and deliver medications more reliably.

Smart Factory Integration

Smart factories leverage IoT sensors, AI analytics, and predictive maintenance to optimize production processes. By continuously collecting and analyzing data, these systems detect inefficiencies, forecast equipment failures, and enhance energy management. Furthermore, digital twins and simulation tools allow manufacturers to test process changes virtually before implementation, minimizing downtime and maximizing productivity.

Conclusion

The future of pharmaceutical manufacturing lies in the integration of automation, continuous production, and smart factory technologies. By combining speed, precision, sustainability, and real-time quality control, modern facilities can meet global healthcare needs efficiently. Ultimately, these innovations ensure safer medications, lower production costs, and a more resilient pharmaceutical supply chain, setting new benchmarks for the industry’s future.