PRODUCTS

Machinery

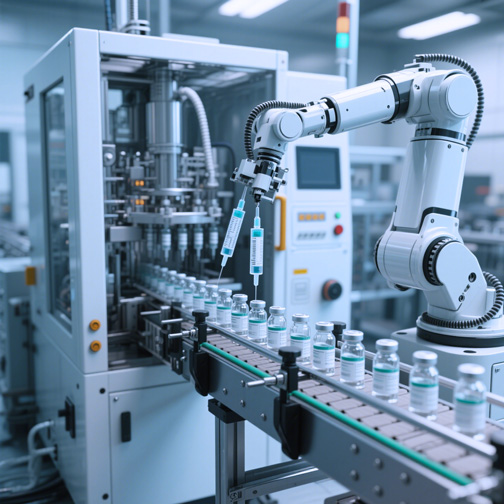

Advanced Equipment for Drug Manufacturing

Explore APEXVIA pharmaceutical machinery, designed to meet the evolving demands of drug manufacturing and healthcare industries. Furthermore, our equipment covers formulation, granulation, smart drug delivery system assembly, and diagnostic device processing. These machines ensure high performance, scalability, and GMP-compliant production for global manufacturers (WHO GMP, FDA, EMA).

Product Categories

APEXVIA pharmaceutical machinery solutions span drug production, packaging, and delivery. They provide GMP-compliant, customizable options for precise API processing, secure packaging, and advanced delivery systems such as injectables and precision dosing devices. Moreover, these products integrate automation and traceability features to enhance production efficiency. For complementary solutions, explore our API & Excipients and Packaging & Devices pages.

Production Machinery

Our production machinery includes core pharmaceutical manufacturing equipment, packaging material lines, and devices for drug delivery systems. Tablet presses, capsule filling machines, liquid filling lines, and specialized equipment for syringe assembly and precision dosing ensure consistent quality and regulatory compliance. In addition, these solutions support both small-scale R&D and large-scale production.

Packaging Machinery

APEXVIA packaging machinery covers primary and secondary packaging, including vial sealing machines, blister packers, labeling systems, cartoning equipment, and shrink-wrapping tools. These solutions guarantee product integrity, regulatory compliance, and operational efficiency. Additionally, they are suitable for a variety of pharmaceutical dosage forms.

Quality Control Machinery

Our quality control machinery provides reliable testing for pharmaceuticals, packaging, and drug delivery systems. This includes dissolution testers, seal integrity analyzers, and functionality testers for syringes and precision devices. Furthermore, these machines support compliance with GMP, FDA, and ISO standards, ensuring high-quality outcomes.

Products Advantages

✅ Pharmaceutical Processing Equipment

High-performance machinery for efficient drug manufacturing.

Precision & Consistency: Delivers uniform mixing, granulation, drying, and tableting for solid and liquid formulations.

Regulatory Compliance: Fully meets GMP, FDA, and EMA standards.

Automation & Traceability: Real-time monitoring and batch tracking enhance quality assurance and efficiency.

Scalable Applications: Suitable for R&D labs, pilot plants, and large-scale manufacturing.

✅ Drug Delivery System Equipment

Advanced solutions for innovative drug delivery formats.

Customized Assembly: Supports injectables, transdermal patches, implants, and other delivery formats.

Smart Integration: Features controlled release, digital dose tracking, and healthcare platform connectivity.

Sterile & Accurate: Ensures safe, contamination-free handling of sensitive pharmaceutical materials.

Flexible Configuration: Easily adapted to various drug types and therapeutic needs.

Product Applications

APEXVIA pharmaceutical machinery supports pharmaceutical manufacturing, drug delivery system development, and medical device production. From solid dosage formulation and liquid filling to sterile packaging and intelligent device assembly, our GMP-, FDA-, and ISO-compliant equipment enhances efficiency, product safety, and speed to market. Moreover, our solutions benefit pharmaceutical companies, biotech firms, and healthcare providers globally.

For complementary solutions, explore our API & Excipients, Packaging & Devices, and Lab Test Services pages.